Laser cutting

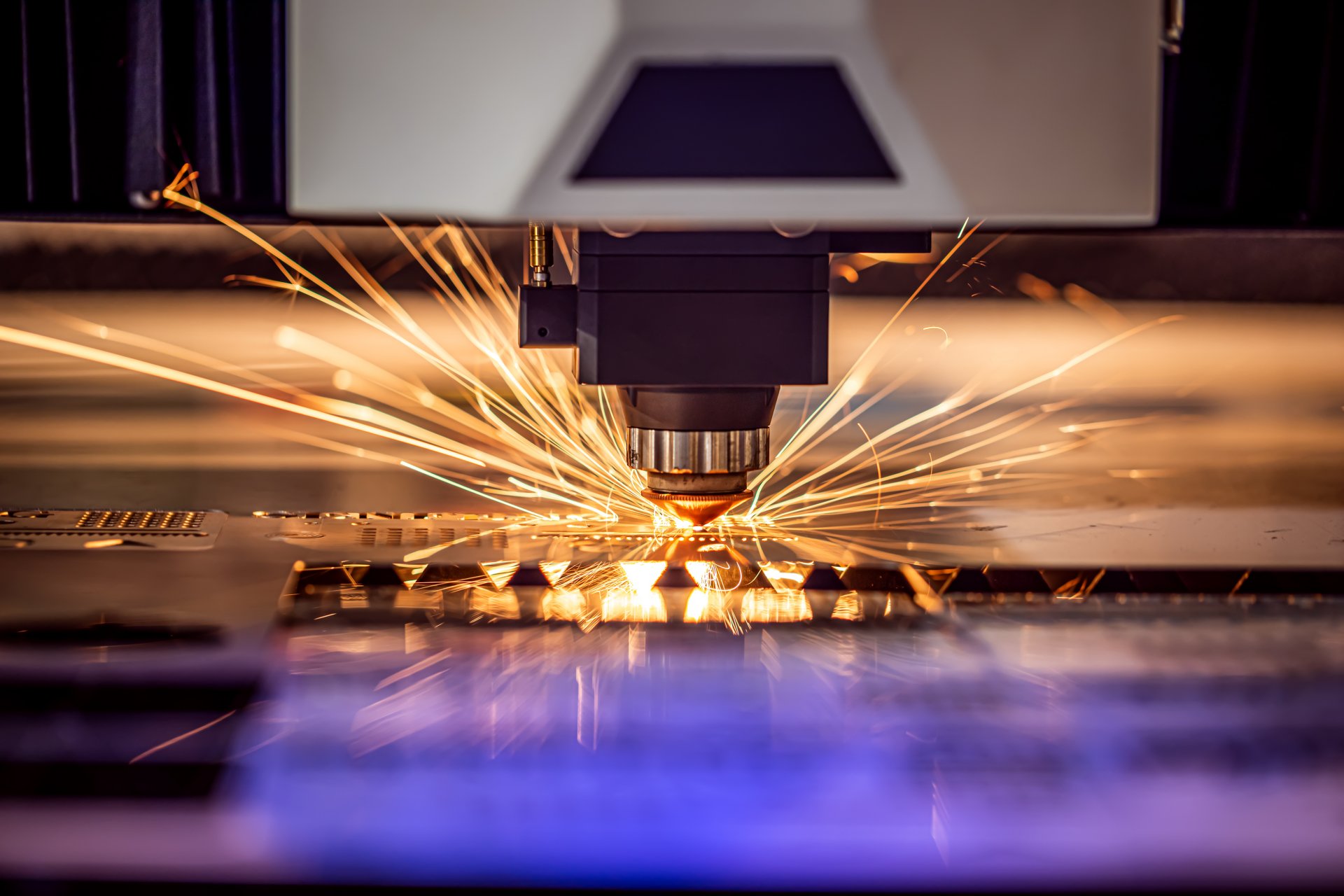

Laser cutting is one of the technologies used in mechanical engineering for material splitting, these are mostly flat materials (stainless steel, steel, aluminum plates). The basis is a laser beam that is shaped and united into a beam. In case, it hits a workpiece, the material heats up so much that it melts or evaporates.

Unlike other procedures of cutting, the laser beam does not produce such a big intensity on a sheet, because it is contactless. Therefore there is not such wastage of a tool or damage or deformation of the workpiece.

The technology of laser cutting of a sheet enables precise shapes and quick treatment. Laser cutting is also economically viable at very small production series (1-10 pieces).

You can supply your material for laser cutting or you can use the material from our assortment.

Main advantages of our machines for laser cutting:

- High quality and accuracy of a cut,

- Smooth and clean surface,

- Ability to cut complicated shapes,

- Low operating and investment costs,

- Maximum dimensions of a plate: 20 mm x 2000 mm x 6000 mm

We prepare price calculation to tailor to your needs and if necessary, we help you with technical details.